Canadian oilfields have high environmental emission requirements. A well-known Canadian-based manufacturer of ternary separators challenged the zero-emission target by using the "all-electric" technology route. For their solution, they chose DCL explosion-proof electric actuators, which have been used in oil applications for more than 10 years.

"0-emission" three-element separator

The separator utilizes state-of-the-art cyclone technology to improve reliability, performance, and physical size compared to standard separators. The entire system is trailer-mounted and towed by a one-ton truck. The heart of the separator utilizes a gas-liquid cylinder cyclone separator (GLCC) and a fully electric control system.

DCL explosion-proof electric actuators with more than 10 years of experience in oil and gas applications.

DCL oil and gas series explosion-proof electric actuator in theSeparators, cementing equipment, tubing equipment, oil trucks and tanks have been applied for 12 years. Currently, major oil equipment producers in China, the United States, Russia, Canada and other countries have chosen DCL explosion-proof series electric actuators for their related products. Following these major oil equipment producers, theDCL explosion-proof electric actuators are reliably used in major oilfields, refineries, pipelines and tank farms around the world.The

Higher reliability of DCL explosion-proof electric actuators

DCL explosion-proof electric actuators, through highly reliable products, have been recognized by the oil industry.

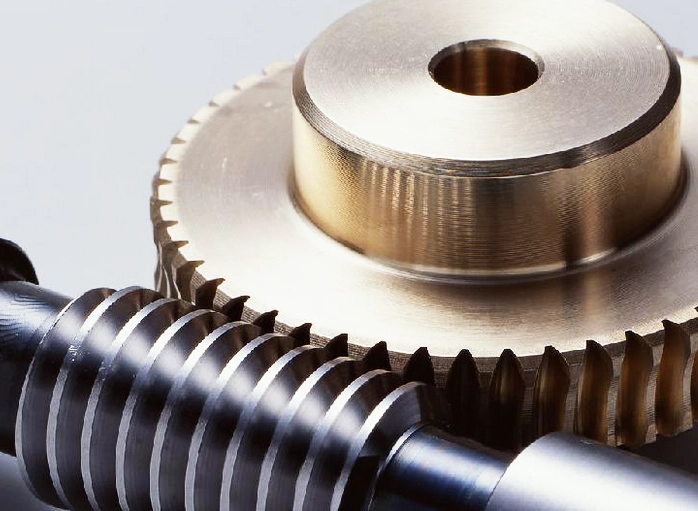

- Ultra-resistant tooth profile, 70% load / 200,000 cycles

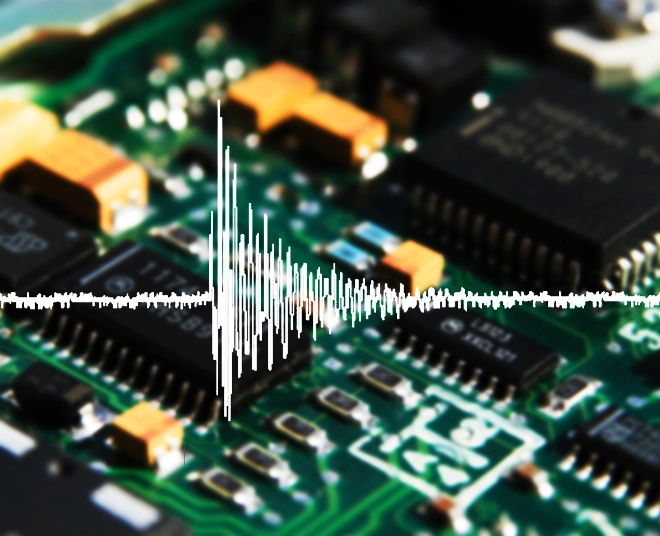

- Wide range EMI immunity, Surge-4kV / EFT-6kV

- Self-developed fully encapsulated control unit, moisture / salt spray resistant

Egong.com.cn 42018502006527 No.

Egong.com.cn 42018502006527 No.