DC-FB3 Instruction Manual

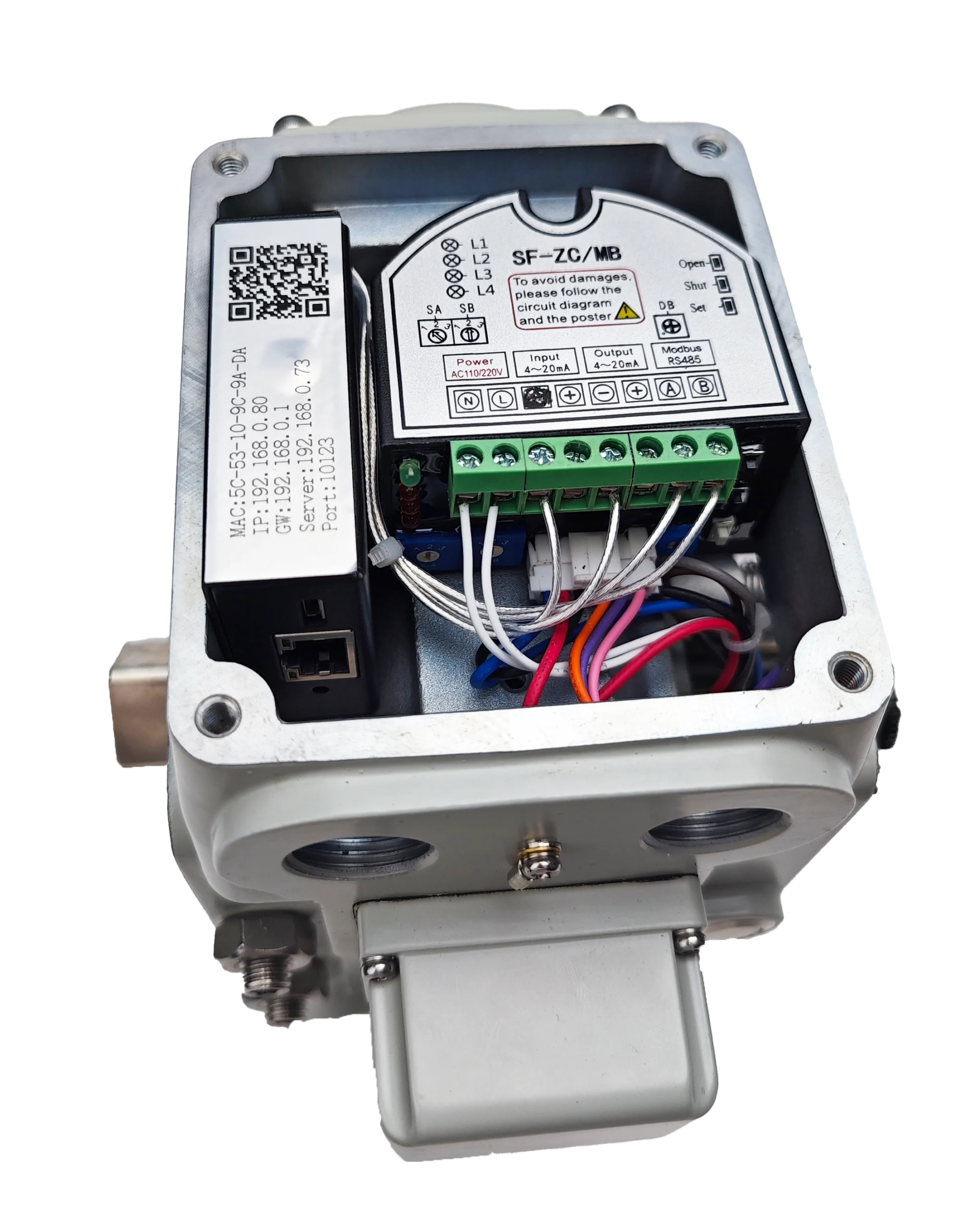

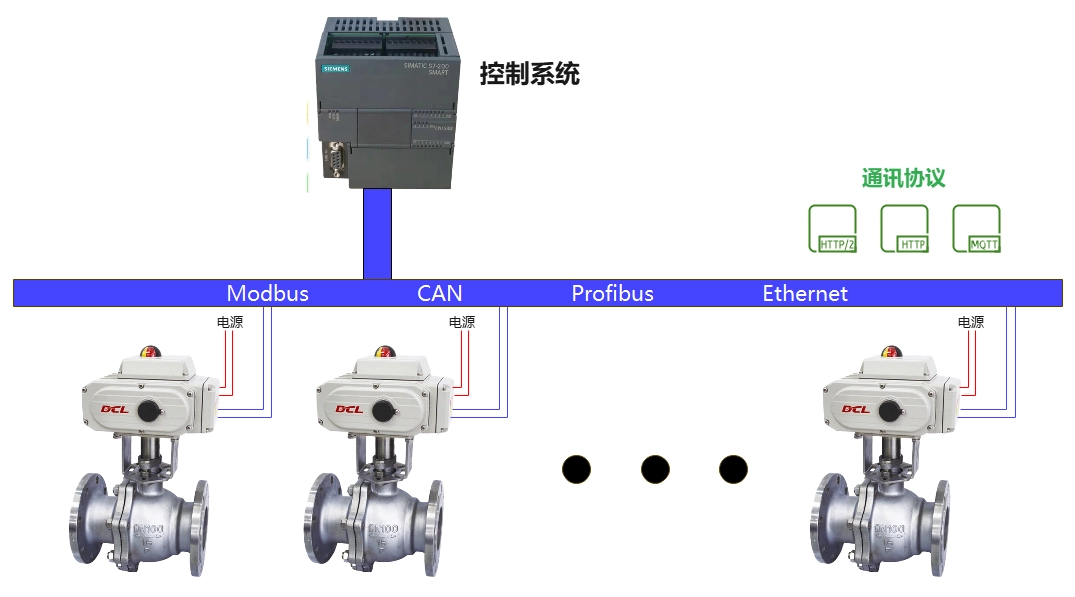

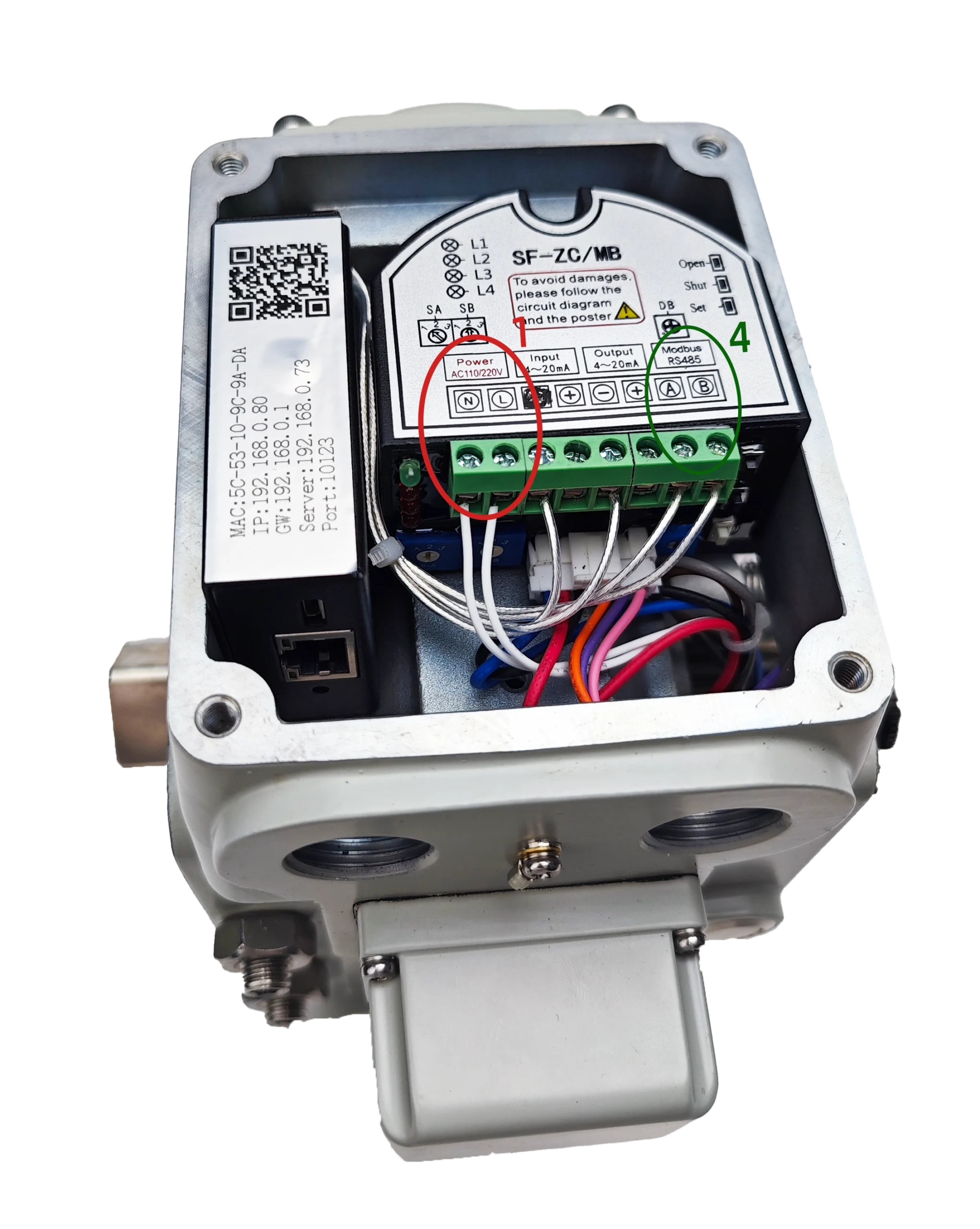

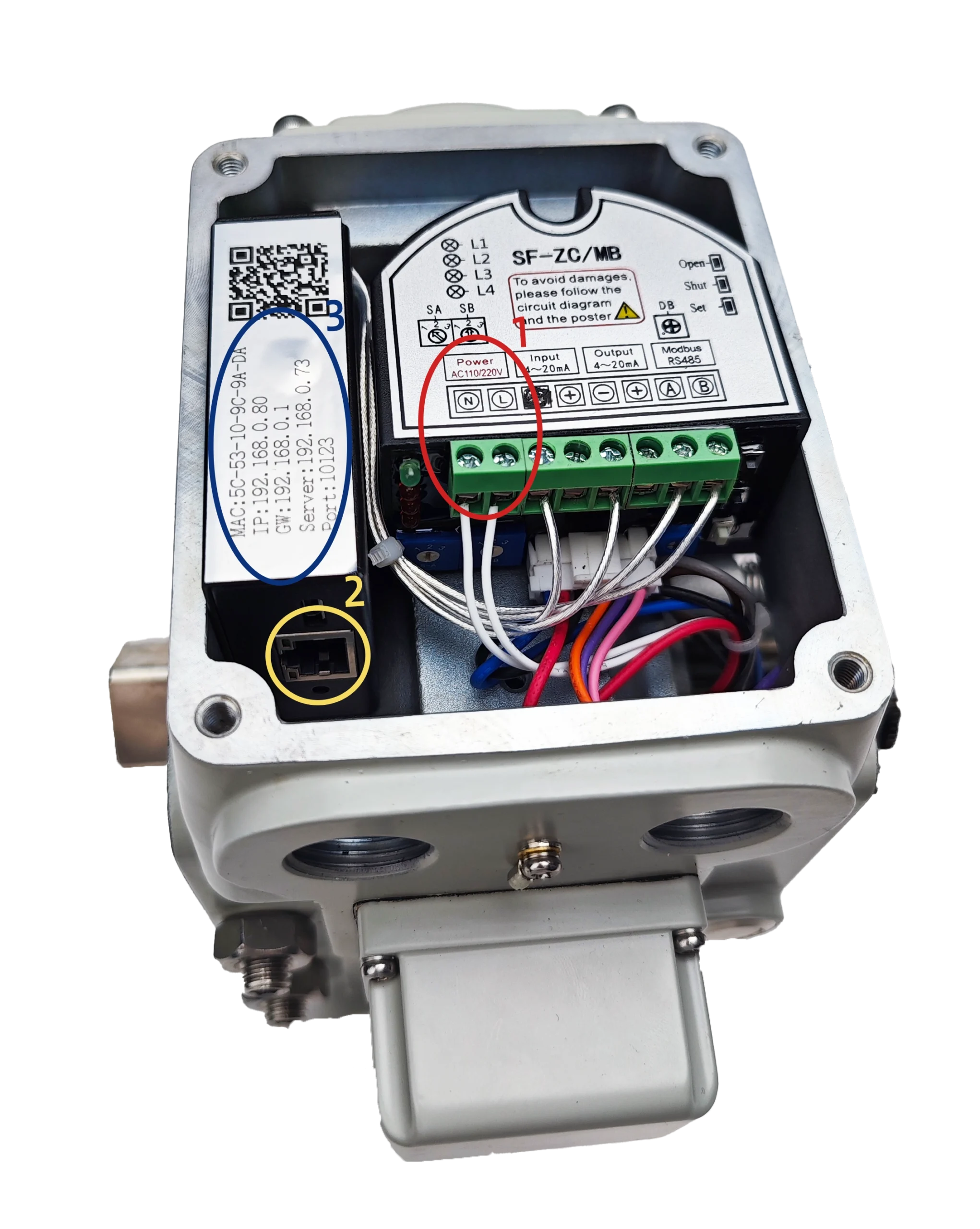

By installing DC-FB3 into DCL electric actuator, it is possible to control the opening of electric valve using Modbus-TCP/IP. The installation is shown in the figure:

1. Control of DCL electric actuators via Modbus-TCP/IP using default parameters

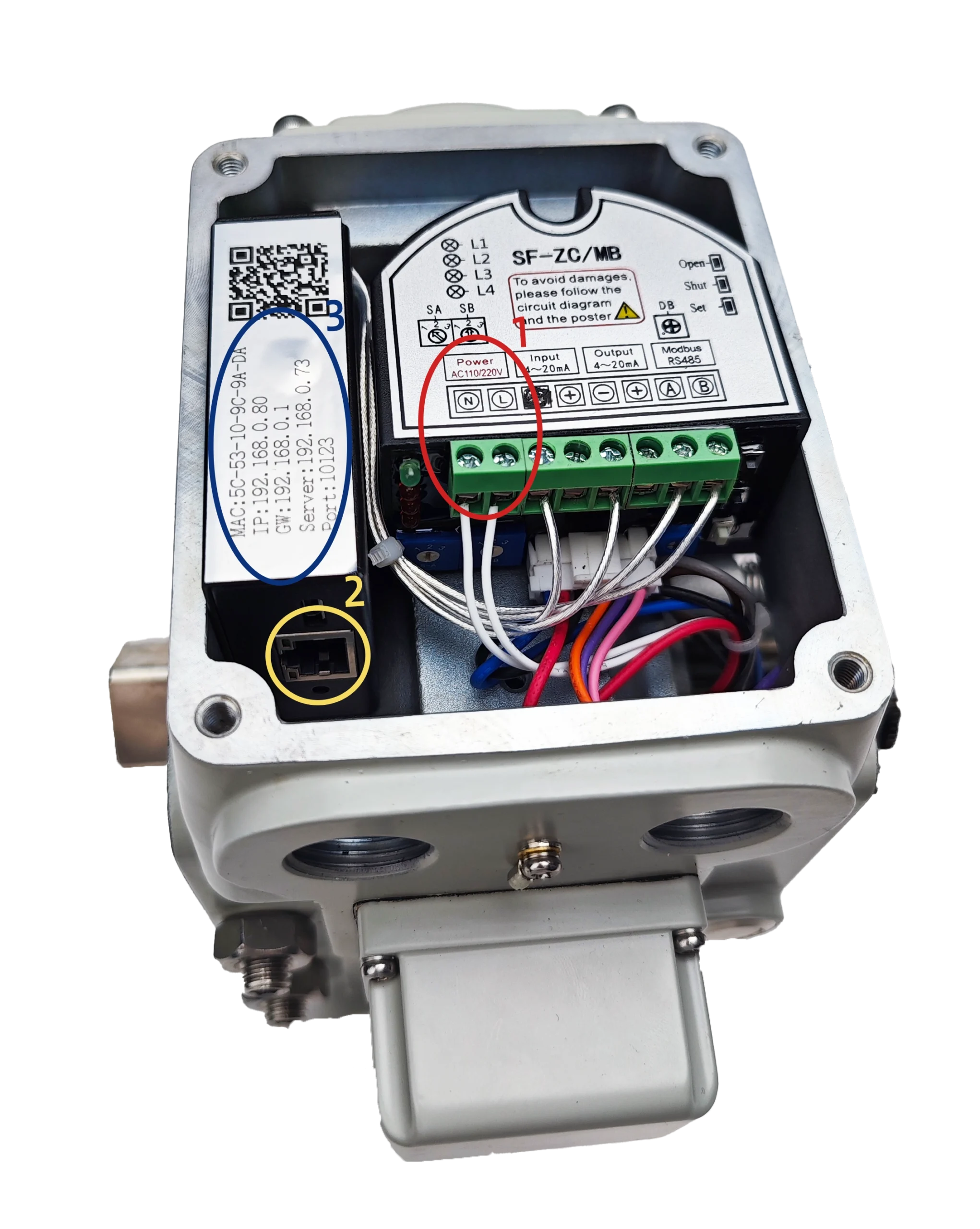

The DC-FB3 is configured in Client mode by default, and you can use the default MAC/IP/Gateway/Server/Port parameter to control the electric actuator via Modbus-TCP/IP. This default parameter is glued to the place marked by blue box 3 in the figure.

When using the default parameters, you can skip step 2 and just follow the Step 3DCL motorized actuators are controlled using Modbus-TCP/IP.

2. Changing TCP/IP network parameters

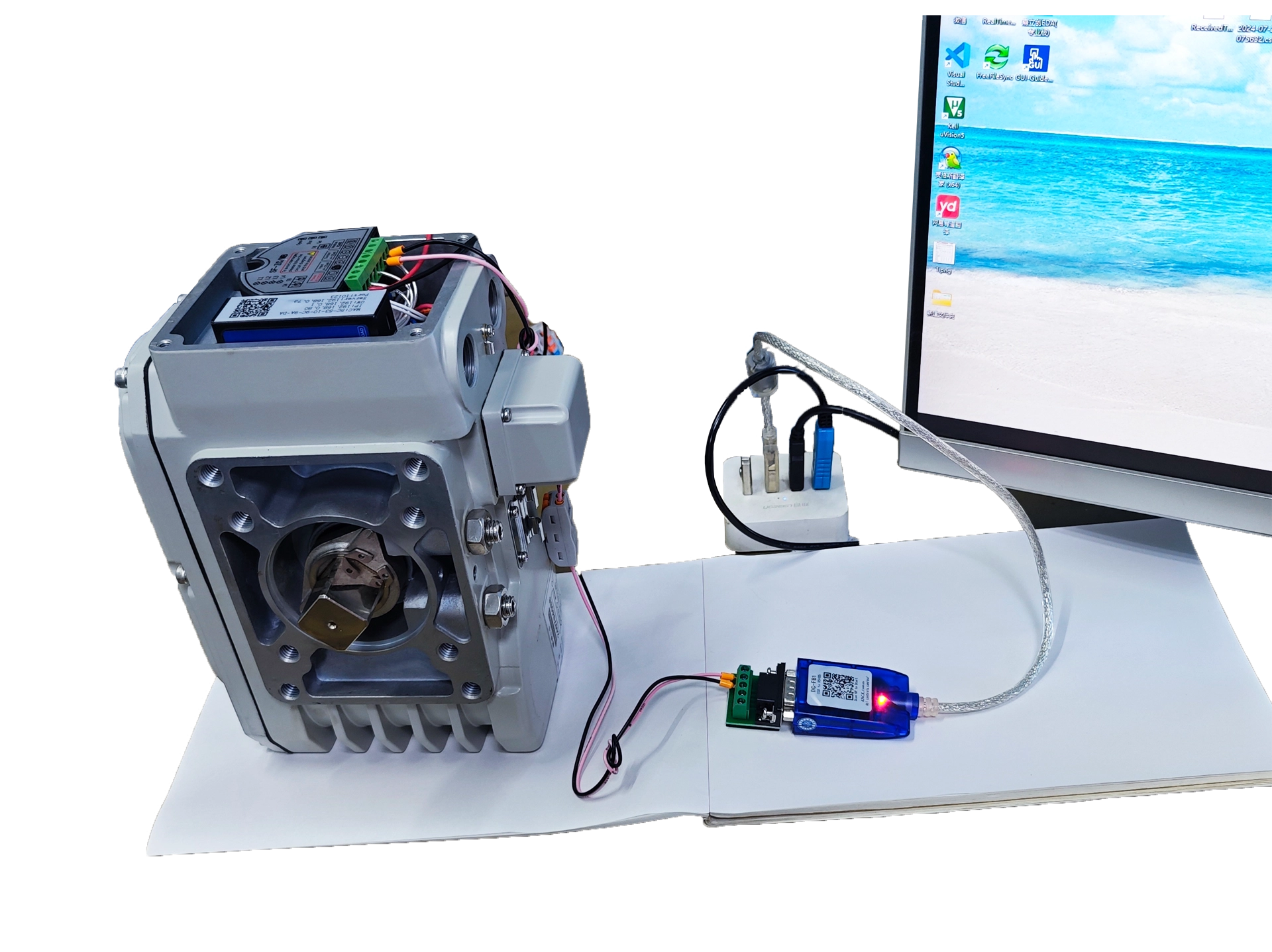

2.1 Using DC-FB1 (USB to RS485), connect DC-FB3 to PC

The DC-FB3 is wired as follows:

- Plug in AC220V power where marked by red box 1.

- The area identified by green box 4 is connected to the RS485 interface (A/B) of the DC-FB1.

- The DC-FB1's USB plugs into the computer.

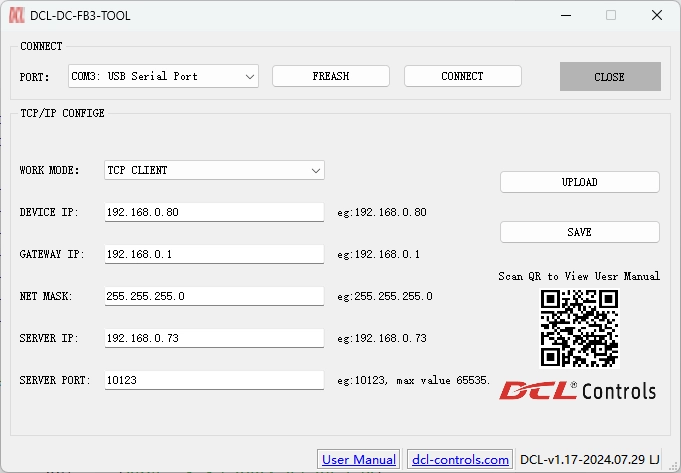

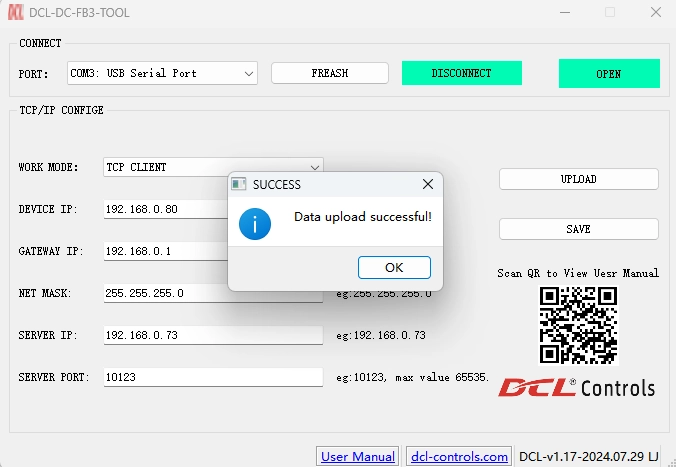

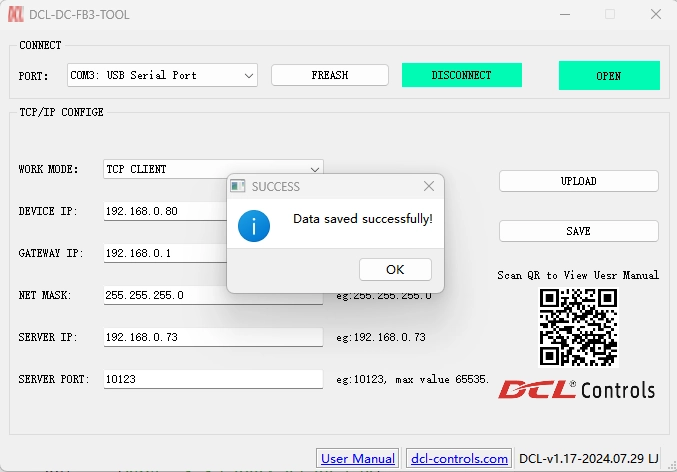

2.2 Use configuration software on your computer to set network parameters

Select the correct port and click CONNECT to connect the DC-FB3.

After successful connection, the setup software will automatically read the parameters in the DC-FB3.

After changing the network parameters, click SAVE and the setup software stores the parameters in the DC-FB3.

3. Using Modbus-TCP/IP, control of electric actuators

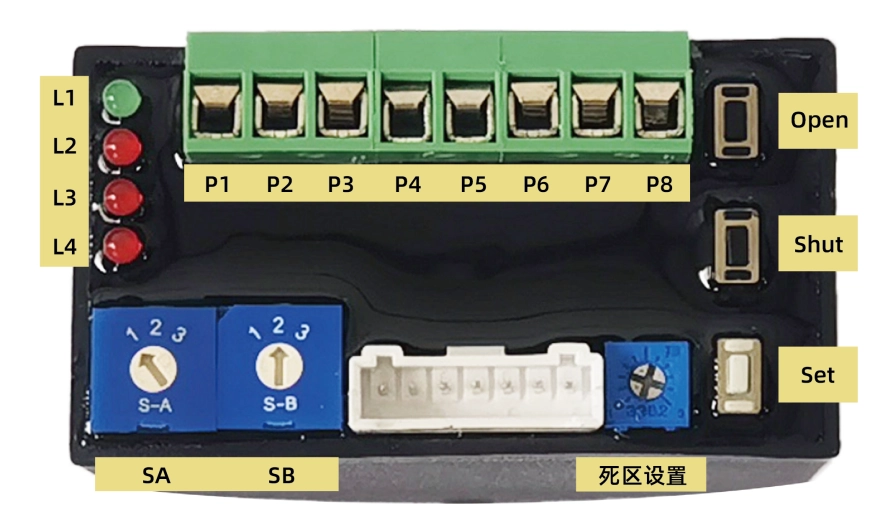

3.1 Panel description

keystrokes

Open: In the "setting state" (i.e. the arrow of the selector switch SA is pointing to "2") press this key to operate the actuator in the open position, release this key to stop the motor, press Set and Open at the same time to calibrate the fully open position.

Shut: Press this key in the "setting state" to operate the actuator in OFF position, release this key to stop the motor, press Set and Shut at the same time to calibrate the full OFF position.

Set: Realize specific functions by working with Open and Shut in the "Setting State".

selector switch

SA: Select the input signal positive and negative mode and setting status, the positive and negative setting must be set in the power-on state to be effective, and the arrow direction corresponds to the function as follows (set to 1 at the factory).

1-Positive action 2-Setting status 3-Reverse action

SB: Setting the safe position, according to which the actuator operates to a specific position in case of loss of external analog control signal (factory setting 2).

1-Operate to fully open position 2-Hold current position 3-Operate to fully closed position

Note: When modbus control mode is used, SB should be kept at 2 speeds.

Deadband value setting potentiometer

Used to set the deadband value. Potentiometer opening from 1-10, corresponding to the deadband value 0.5%-5.0% (factory deadband value is set to 1.5%).

indicator light

L1: Green, power indication, the light is on when power is connected between N and L of the servo controller power supply terminal;

L2: Red, Input Signal Failure Fault Indication, Lights up when the input signal fails;

L3: Red, position detection circuit fault indication, open potentiometer leads open, shorted, or damaged itself when the light is on;

L4: Red: Jamming fault indication, light comes on when jamming occurs.

3.2 Hardware Wiring

- Plug in AC220V power where marked by red box 1.

- Access the RJ45 network cable where marked by yellow box 2.

3.3 Settings

If the arrow of selector switch SA points to position "2″, it enters the setting state. In the setting state, it is possible to carry out travel calibration, selection of input signal failure processing method, deadband value setting, manual operation and output current correction.

Stroke Calibration

All-off position calibration: Adjust the valve to the fully closed position by pressing the Open and/or Shut buttons, first press the Set button without letting go, then press the Shut button, keep both buttons pressed at the same time for about 4S clocks, when the indicator L2 is on, release the Shut and Set buttons at the same time, L2 goes off, and the calibration of the fully closed position is completed.

Full open position calibration: Adjust the valve to the fully open position by pressing the Open and/or Shut buttons, first press the Set without releasing, then press the Open button, keep both buttons pressed at the same time for about 4S clocks, when the indicator light L2 is on, release the Open and Set buttons at the same time, L2 goes off, and the calibration of the fully open position is completed.

Deadband value setting

The deadband setting potentiometer turns clockwise to increase the deadband value, and counterclockwise to decrease the deadband value. There is a scale on the front side of the potentiometer, and every time the potentiometer is rotated by one degree, the deadband value changes by 0.5%. When the deadband value is set to less than 0.5%, the servo controller will process it according to 0.5%.

The valve can be opened and closed manually by pressing Open or Shut in the setting state.

3.4 Operation

Set the selector switch SA to position "1" or "3" to enter automatic operation.

- After power-on, the actuator defaults to follow the 4-20mA input signal for opening adjustment.

- Sending commands via Modbus enables the actuator to work in communication control mode and automatically return to analog control mode after the actuator is powered off and restarted.

Note: When communication control is used, ensure that SB is in 2nd gear to prevent restart operation to a safe position.

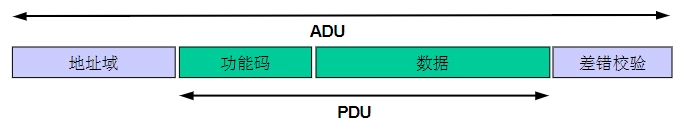

3.5 Application Layer

ADU

function code

| ID | 名称 | 描述 |

|---|---|---|

| 0x03 | 读多个寄存器 | 在一个远程设备中,使用该功能码读取保持寄存器连续块的内容 |

| 0x06 | 写单个寄存器 | 在一个远程设备中,使用该功能码写单个寄存器 |

| 0x10 | 写多个寄存器 | 在一个远程设备中,使用该功能码写连续寄存器块(1 至约 120 个寄存器) |

register list

| 寄存器地址 | 寄存器位 | 信号组 | 信号名 | 最小值 | 最大值 | 单位 | 读/写 | 类型 | 真值表 | 描述 |

|---|---|---|---|---|---|---|---|---|---|---|

| 0x0010 | b15-b5 | \ | \ | \ | \ | \ | r/w | hex | 保留0 | 保留 |

| b5 | \ | \ | \ | \ | \ | r/w | hex | 保留0 | 保留 | |

| b4 | control | stop | \ | \ | \ | r/w | hex | 1:停止, 0:正常 | stop running | |

| b3 | \ | \ | \ | \ | \ | r | hex | 保留0 | 保留 | |

| b2 | \ | \ | \ | \ | \ | r | hex | 保留0 | 保留 | |

| b1-b0 | control | mode | \ | \ | \ | r/w | hex | 1: 通讯控制 其他: 退出通讯控制 | 控制模式 | |

| 0x0011 | b15-b0 | control | SetOpenDegree | 0 | 10000 | % | r/w | int/hex | 0-10000对应 0-100%开度 | 控制阀门的开度(比率系数1/100) |

| 0x0012 | b15-b0 | \ | \ | \ | \ | \ | r | hex | 保留0 | 保留 |

| 0x0013 | b15-b0 | \ | \ | \ | \ | \ | r | hex | 保留0 | 保留 |

| 0x0014 | b15-b0 | \ | \ | \ | \ | \ | r | hex | 保留0 | 保留 |

| 0x0015 | b15-b0 | \ | \ | \ | \ | \ | r | hex | 保留0 | 保留 |

| 0x0016 | b15-b0 | \ | \ | \ | \ | \ | r | hex | 保留0 | 保留 |

| 0x0017 | b15-b0 | \ | \ | \ | \ | \ | r | hex | 保留0 | 保留 |

| 0x0018 | b15-b6 | \ | \ | \ | \ | \ | r | hex | 保留0 | 保留 |

| b5 | infor | errPosition | \ | \ | \ | r | hex | 1: 位置信号故障 | 位置信号故障标志 | |

| b4 | infor | errSignal | \ | \ | \ | r | hex | 1: 输入信号故障 | 输入信号故障标志 | |

| b3 | infor | overTorqueFlag | \ | \ | \ | r | hex | 1: 过载 | 过载标志 | |

| b2 | infor | stuckFlag | \ | \ | \ | r | hex | 1: 堵转 | 堵转标志 | |

| b1 | infor | openRunFlag | \ | \ | \ | r | hex | 1: 关阀中 | 开阀标志 | |

| b0 | infor | closeRunFlag | \ | \ | \ | r | hex | 1: 开阀中 | 关阀标志 | |

| 0x0019 | b15-b0 | infor | openDegree | 0 | 10000 | % | r | int/hex | 0-10000对应 0-100%开度 | 当前阀门的开度(比率系数1/100) |

| 0x001A | b15-b0 | \ | \ | \ | \ | \ | r | hex | 保留0 | 保留 |

| 0x001B | b15-b0 | \ | \ | \ | \ | \ | r | hex | 保留0 | 保留 |

| 0x001C | b15-b0 | \ | \ | \ | \ | \ | r | hex | 保留0 | 保留 |

| 0x001D | b15-b0 | \ | \ | \ | \ | \ | r | hex | 保留0 | 保留 |

| 0x001E | b15-b0 | \ | \ | \ | \ | \ | r | hex | 保留0 | 保留 |

| 0x001F | b15-b0 | \ | \ | \ | \ | \ | r | hex | 保留0 | 保留 |

| 0x0040 | b15-b0 | config | cfgMode | 1 | 127 | \ | rw | hex | 0x0000: 进入常规模式 0xA501: 进入配置模式 | 模式选择,在配置模式下才能修改配置参数 |

| 0x0041 | b15-b0 | config | cmm_addr | 1 | 127 | \ | rw | hex | 1~127 | 设置通讯地址 |

| 0x0042 | b15-b0 | config | cmm_baudrate | \ | \ | \ | rw | hex | 0: 波特率4800 1: 波特率9600 2: 波特率19200 3: 波特率115200 | 设置波特率 写入时按真值表写波特率 读取时按真值表返回 |

| 0x0043 | b15-b0 | \ | \ | \ | \ | \ | r | hex | 保留0 | 保留 |

| 0x0044 | b15-b0 | \ | \ | \ | \ | \ | r | hex | 保留0 | 保留 |

| 0x0045 | b15-b0 | \ | \ | \ | \ | \ | r | hex | 保留0 | 保留 |

| 0x0046 | b15-b0 | \ | \ | \ | \ | \ | r | hex | 保留0 | 保留 |

| 0x0047 | b15-b0 | \ | \ | \ | \ | \ | r | hex | 保留0 | 保留 |

| 0x0048 | b15-b0 | \ | \ | \ | \ | \ | r | hex | 保留0 | 保留 |

3.6 Examples of communication commands

Control valve position

- Enter the communication control mode:

Send → ◇01 10 00 10 00 01 02 00 01 65 00

Receive ◆01 10 00 10 00 00 01 00 0C - Set valve position: 0%

Send → ◇01 10 00 11 00 01 02 00 00 A5 11

Receive ◆01 10 00 11 00 01 51 CC - Set valve position: 50% (5000 -> 0x1388)

Send → ◇01 10 00 11 00 01 02 13 88 A8 47

Receive ◆01 10 00 11 00 01 51 CC - Set valve position: 100% (10000 -> 0x2710)

Issued: ◇01 10 00 11 00 01 02 27 10 BF 2D

Receive ◆01 10 00 11 00 01 51 CC - stop running

Hair → ◇01 10 00 10 00 01 02 00 11 64 CC

Receive ◆01 10 00 10 00 00 01 00 0C

Read valve status

- Send → ◇01 03 00 18 00 00 02 44 0C

- Receive ◆ 01 03 04 00 30 00 00 FA 3C

Egong.com.cn 42018502006527 No.

Egong.com.cn 42018502006527 No.