Why are actuators in certain areas explosion-proof?

What's the explosion?

A prerequisite for an explosion is that the explosive substance must be mixed to a certain extent with oxygen to cause a chemical reaction under suitable ignition conditions. If the reaction speed exceeds the speed of sound, it is defined as an explosion.

An explosive mixture that has accumulated to a certain level suddenly explodes and causes a destructive effect in the form of a blast wave.

What is explosion-proof?

Explosions can be prevented by limiting the occurrence of any of these three conditions. In many applications, the presence of explosive substances and oxygen is unavoidable, so the source of ignition must be limited.

Electrical equipment is a potential source of ignition, resulting in increased surface temperatures during operation, electrostatic discharge, or sparks caused by an instantaneous electric current.

Explosion-proof electrical equipment is designed to avoid high surface temperatures and sparks during operation. As a result, explosion-proof electrical equipment does not become a potential source of ignition.

Classification of potentially explosive environments

Generally electrical equipment for explosive atmospheres can be divided into two categories.

Class I electrical equipment for coal mines;

Class II electrical equipment for explosive atmospheres other than coal mines.

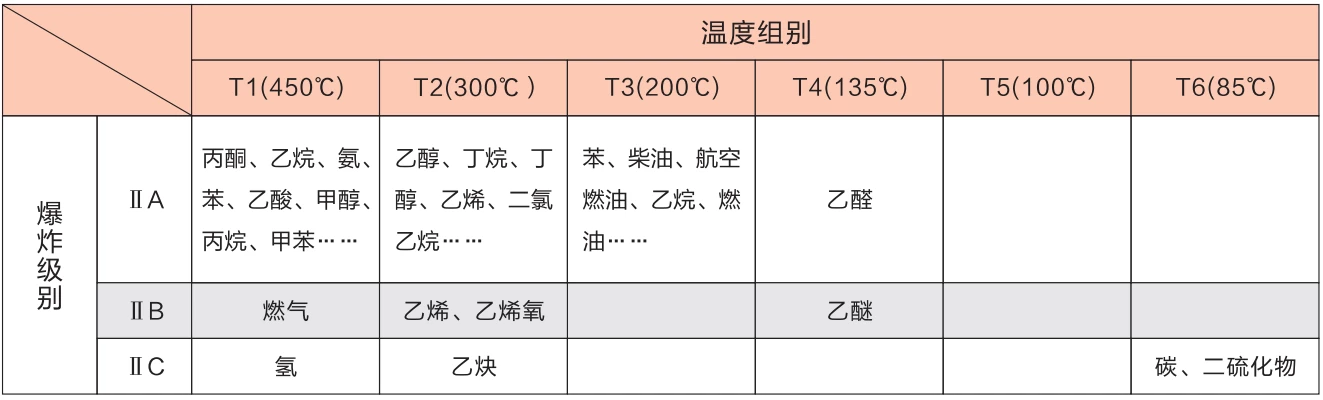

For Class II electrical equipment, according to the maximum test safety clearance for explosive gases (explosion-proof) and the minimum test ignition current (intrinsically safe) can be divided into three explosion levels IIA, IIB, IIC, and IIB equipment can be applied to the conditions of use of IIA equipment, IIC equipment can be applied to the conditions of use of IIA and IIB equipment.

For Class II electrical equipment, according to the permissible maximum surface temperature can be divided into T1 (450 ° C), T2 (300 ° C), T3 (200 ° C), T4 (135 ° C), T5 (100 ° C), T6 (85 ° C) and other six temperature groups, and the higher temperature group of equipment can be applied to the lower temperature group of conditions of use.

Explosive gases above 90% are included in explosion classes II A, II B and temperature groups T1 ~ T4.

How is explosion-proofing achieved?

There are different ways to make electrical equipment suitable for explosive environments, which are described in detail in standards such as GB3836, IEC60079 and EN50014.

DCL explosion-proof series electric actuators are manufactured according to the explosion-proof type of "explosion-proof" (Exd), which meet the requirements of GB3836.1-2010, GB3836.2-2010, EN/IEC 60079-0s EN/IEC 60079-1, EN/IEC 60079-31s EN ISO/IEC 80079-36, EN ISO/IEC 80079-37 standards. 31 s EN ISO/IEC 80079-36, EN ISO/IEC 80079-37 standard requirements.

Flameproof (Exd)

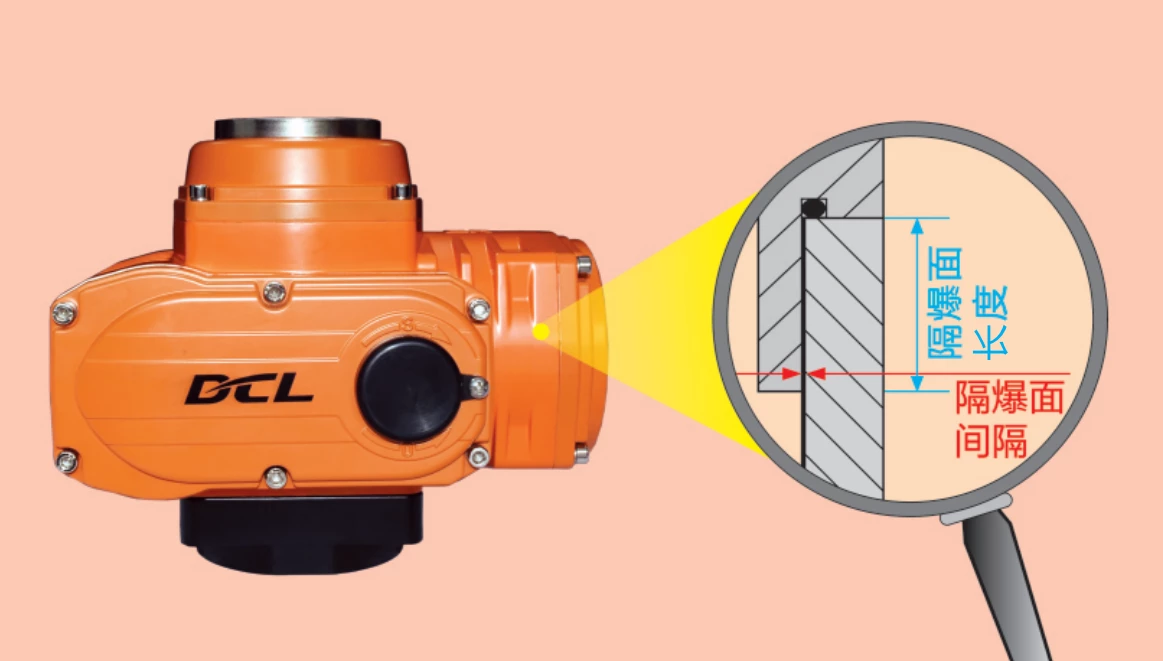

Explosion-proof actuators allow for explosions inside the device. The explosion-proof surfaces of the housings are designed to prevent internal sparks or explosive carriers from coming into contact with the outside world, which is ensured by a suitable clearance of the surfaces and a sufficiently large length of the surfaces. At the same time, a robust casing can withstand the high pressures generated by an internal explosion without being damaged.

The following components of the DCL explosion-proof actuators are designed and manufactured in accordance with explosion-proof standards:

♦Motor chamber ♦Electrical component chamber ♦Wiring chamber

Explosion-proof grade

DCL explosion-proof series electric actuators have an explosion-proof rating:

ExdllCT4Gb

Ex-explosion proof marking

d-explosion-proof type, indicated as "explosion-proof";

U - equipment category, indicating electrical equipment for explosive atmospheres other than coal mines;

C - Explosive class, which determines the dimensions (length and clearance) of each explosion-protected joint of the actuator;

T4 A temperature group indicating that the maximum permissible surface temperature of the actuator is 135 °C.

Gb-Indicates the device protection level.

Egong.com.cn 42018502006527 No.

Egong.com.cn 42018502006527 No.