Rotork talks about digitalization of electric valves

Rotork recently discussed the importance of digitalization for valve automation and control in the European Control Engineering magazine.

Industrial Internet of Things (IIoT) technology uses electronic devices such as sensors to collect and share data, and uses the arithmetic power of cloud platforms to deeply mine and utilize the data. This technology has spawned a gradual evolution of industrial process control towards networking and intelligence.

Modern technological innovation is no longer limited to product functionality; it is in how to save and utilize the data generated during the application of the product in order to achieve faster and more appropriate system arbitration, which reduces the cost of time and money and improves the performance and safety of the flow control system at the same time.

The value of the data provided by the digitization of the system cannot be overemphasized. However, in order to receive the data, the site needs to be equipped with the right equipment capable of retrieving useful information. When operating hundreds of valves in the field, having a smart actuator that provides advanced data logging capabilities is critical to a powerful digital asset management network. At this point, IoT platform software running on a cloud platform is required to ensure centralized monitoring and management of numerous electric actuators.

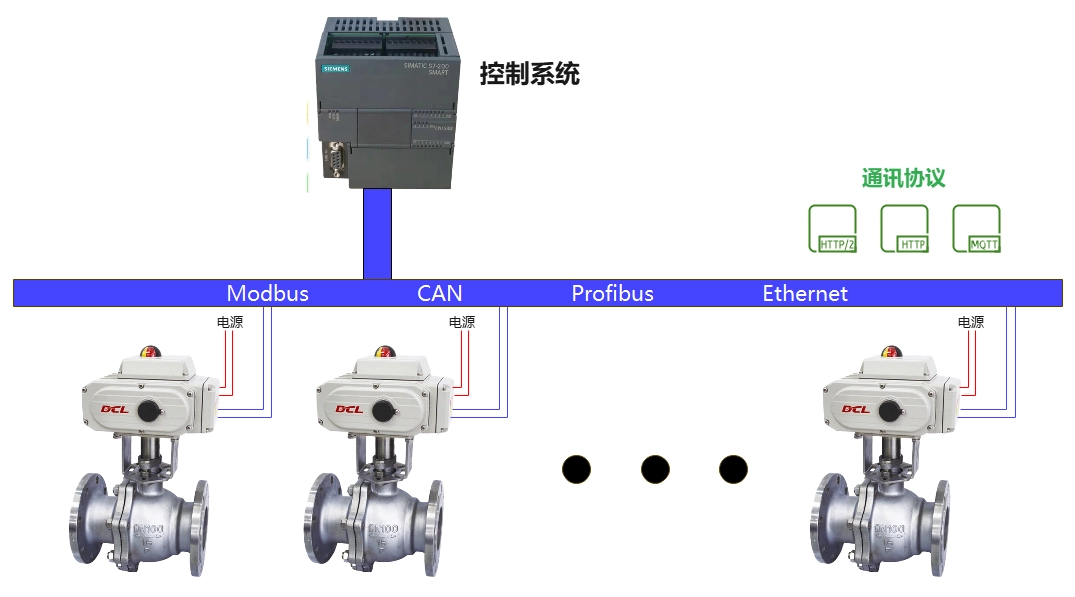

Bus-based Distributed Control System (DCS) Automates Flow Control System

Data communication is an essential part of modern actuators and motorized valves. IoT control systems for valve actuators allow field operators to control operations at any time, 365 days a year, while monitoring up to 200+ actuators on a fault-tolerant field network and up to 20 kilometers without repeaters.

To meet these requirements, engineers incorporate field communication networks that allow plant equipment to be controlled and monitored through a distributed control system (DCS). In order for a distributed control system to operate effectively, it needs a master station. This provides the vital connection between the field devices and the central DCS.

Master stations are typically available in single, dual or hot standby configurations. The single option provides redundant host connections and redundant field network loops, while the dual configuration sees two fully isolated, independent units mounted side-by-side. The hot standby variant provides full redundancy and each interface is replicated. In the event of a failure, switching to standby is seamless with no loss of data or control.

Cloud-Based Actuator IoT Enables Intelligent Flow Control Systems

There are also significant benefits to digitizing the maintenance and management of assets through a cloud-based actuator IoT system. The AliCloud-based DCL actuator IoT system can deeply compute motion data and diagnostic data stored in electric actuators.(torque, operation, temperature, etc.) as a means of analyzing actuator performance and valve performance.Now you can retrieve and process this data in the most efficient way and present it in a streamlined UI. So operators can get a full picture of what's really happening in the field to minimize downtime and make faster, more informed decisions.

The digitization and networking of modern smart electric actuators provides simplified, safe and cost-effective solutions for actuator application scenarios to support long-term operational efficiency and flow control device management.

Egong.com.cn 42018502006527 No.

Egong.com.cn 42018502006527 No.