- Explosion protection class Exd II CT4Gb

- Protection class IP68

- For use in potentially explosive environments

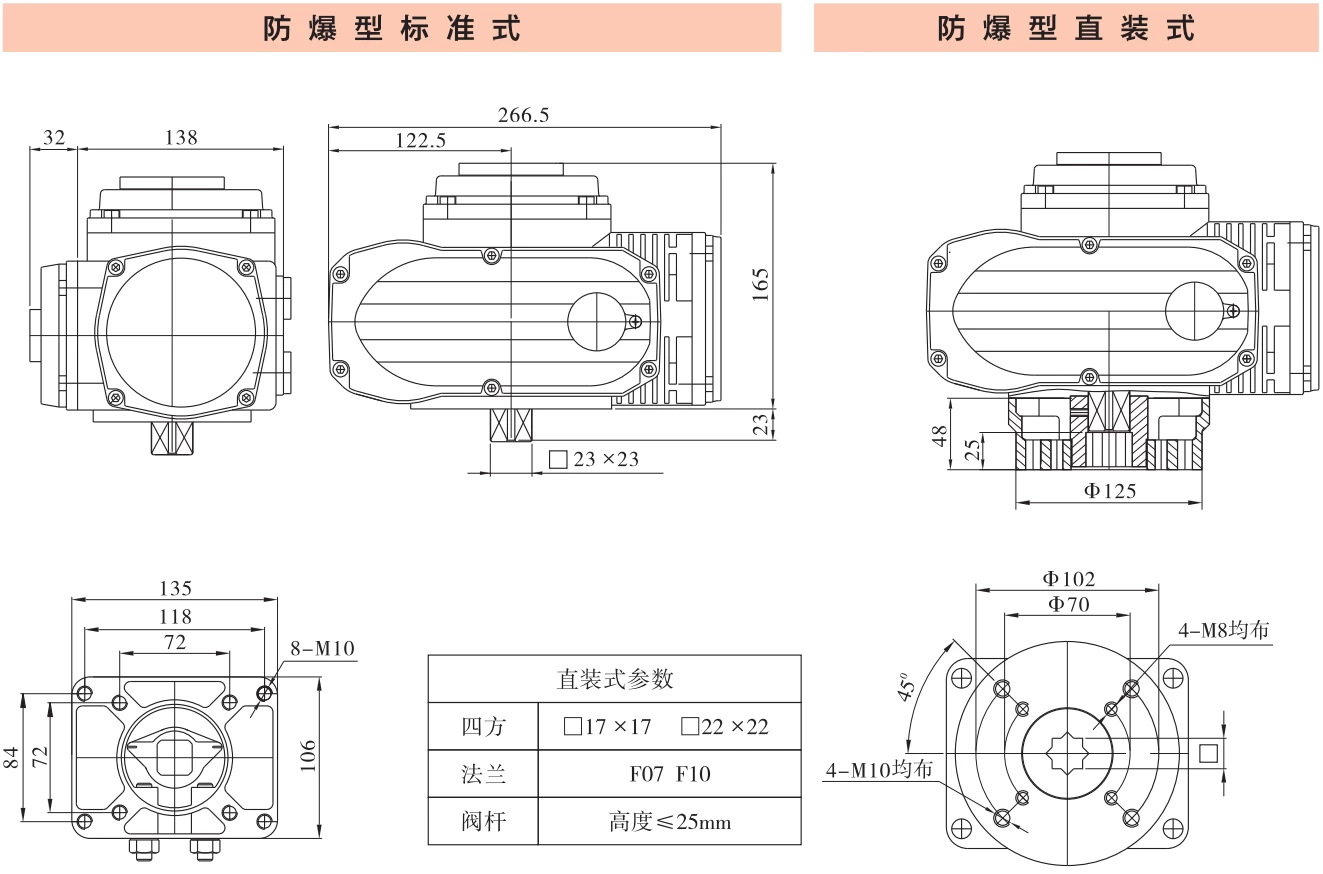

- Matching Angle Stroke Valve

Adaptive Valve

Partial rotation

damper

0~90°

Torque/Time

400Nm/30S

selectable

200Nm/15S

400Nm/60S

Type of control

switching type

regulating type

Supply Voltage

DC24V

AC110V

AC220V

AC380V

Input/Output Signal

4~20mA

0~10V

Level | Contacts

Modbus-RTU | CAN | Ethernet

optional

Over-torque protection

Power failure reset

Self-heating dehumidification

self-diagnosis

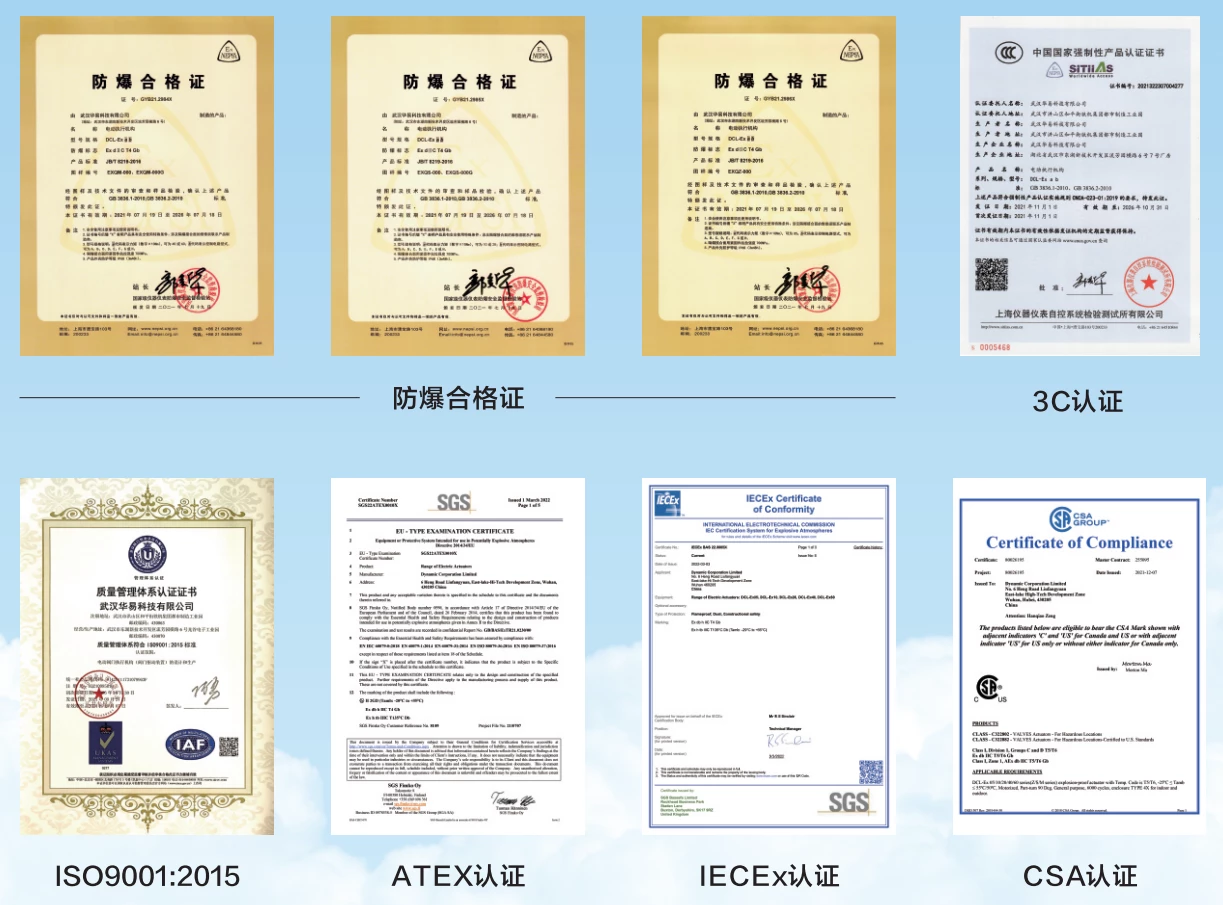

Explosion-proof certificate

Adjustment method

regulating type

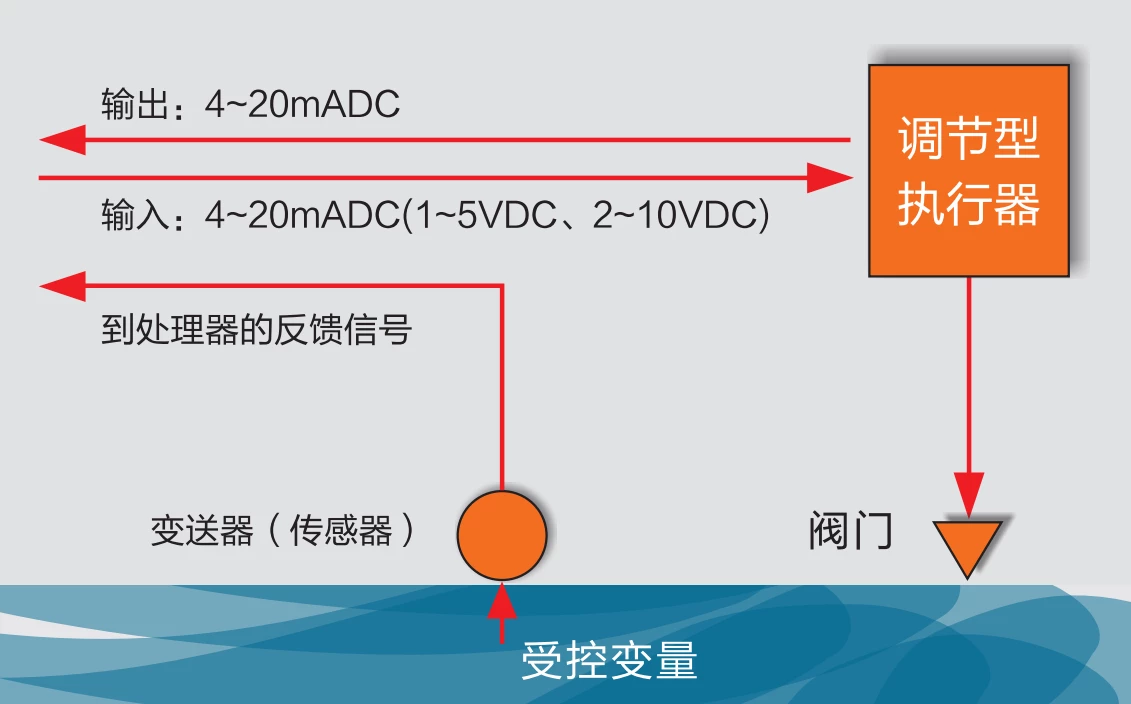

The servo controller is placed inside the actuator and receives commands from the central control system to drive the valve to the appropriate opening position based on changes in the controlled variables in the pipeline (flow, pressure, temperature, level).

Adopting S4 intermittent type working system, the working frequency is up to 1200 times per hour.

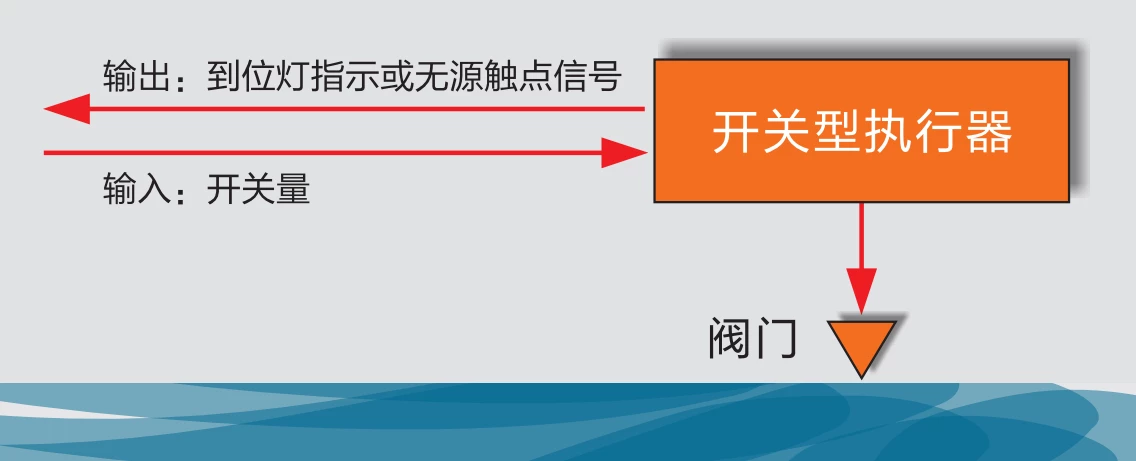

switching type

A, B, D, G, H control circuits

Switching models have only fully open and fully closed limit positions; intermediate positions can be preset if desired (models B, D, G, and H). Upon receipt of the appropriate command, the actuator will drive the valve to the fully open, or fully closed, or intermediate positions.

The S2 short-time type working system is adopted, and the continuous running time does not exceed 15 minutes.

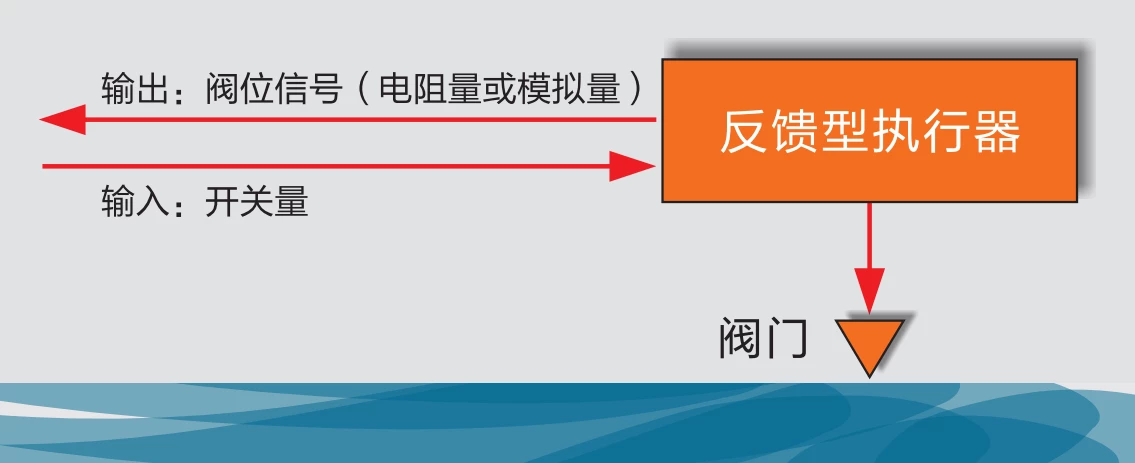

feedback-based

C, D, F type control circuits

In the process of driving the valve, the actuator feeds back the valve position signal to the central control system at the same time. types C and D feed back the resistive valve position signal, and type F feeds back the analog valve position signal.

The S2 short-time type working system is adopted, and the continuous running time does not exceed 15 minutes.

Functional Features

Servo Control Modules

DCL's unique circuit design, imported industrial-grade electronic components, and modern circuit board manufacturing process ensure the high quality and reliability of the servo controller. The circuit board is resin molded for better vibration and moisture resistance. Unique electronic braking function, so that the actuator positioning without oscillation, damping characteristics of 0 cycles (standard regulations not more than 3.5 cycles)".

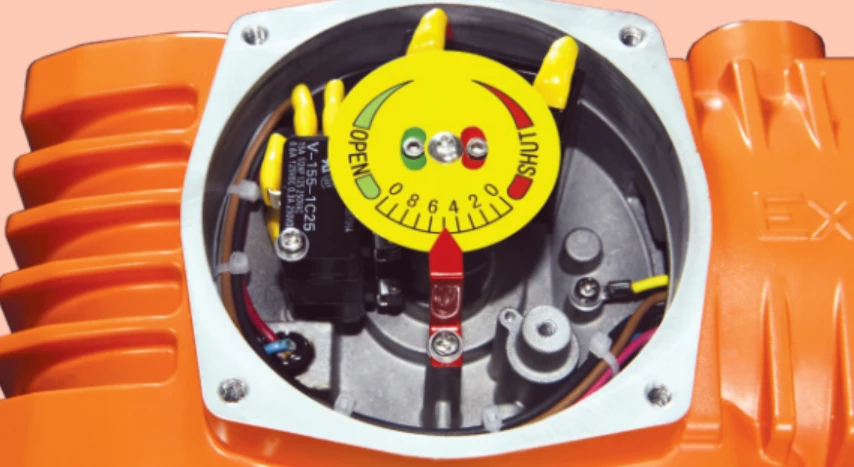

Micro-adjustment of electrical limit travel

With DCL's unique patented design, the actuator's open and closed electrical limit travel can be easily adjusted with only a hexagonal wrench. At the same time, the unique micro-adjustment function makes it possible to adjust the electrical limit travel more accurately.

Patent No.: ZL 201020214725.8

electrical machinery

Due to the working characteristics of the valve, the actuator is required to have the ability to start at full load in the opening, closing and any intermediate position of the valve, which requires the motor of the actuator to have a high starting torque. This requires the actuator motor to have a high starting torque. At the same time, due to the need for version (opening) adjustment, the motor must have a small rotating inertia, and DCL series electric actuator motors have been specially designed to meet these requirements.

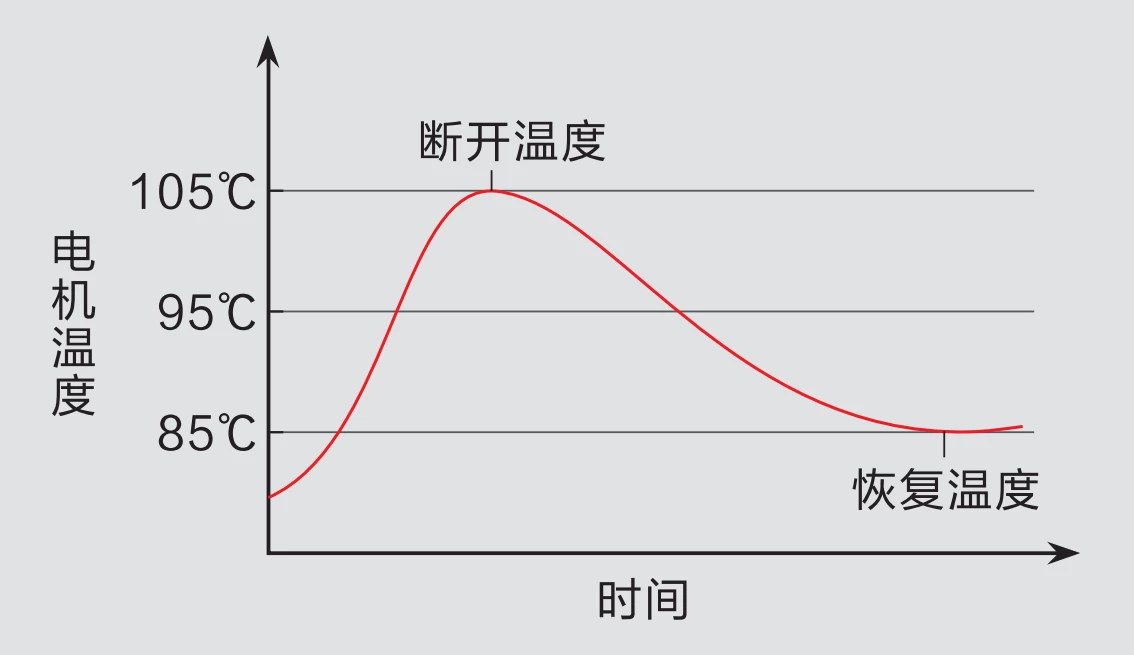

When the actuator is blocked, the motor temperature will rise rapidly. When the motor temperature reaches 1252, a PTC thermal protector embedded in the motor windings cuts the circuit to protect the motor and control system. When the motor temperature drops to 90-105W, the circuit will be turned back on.

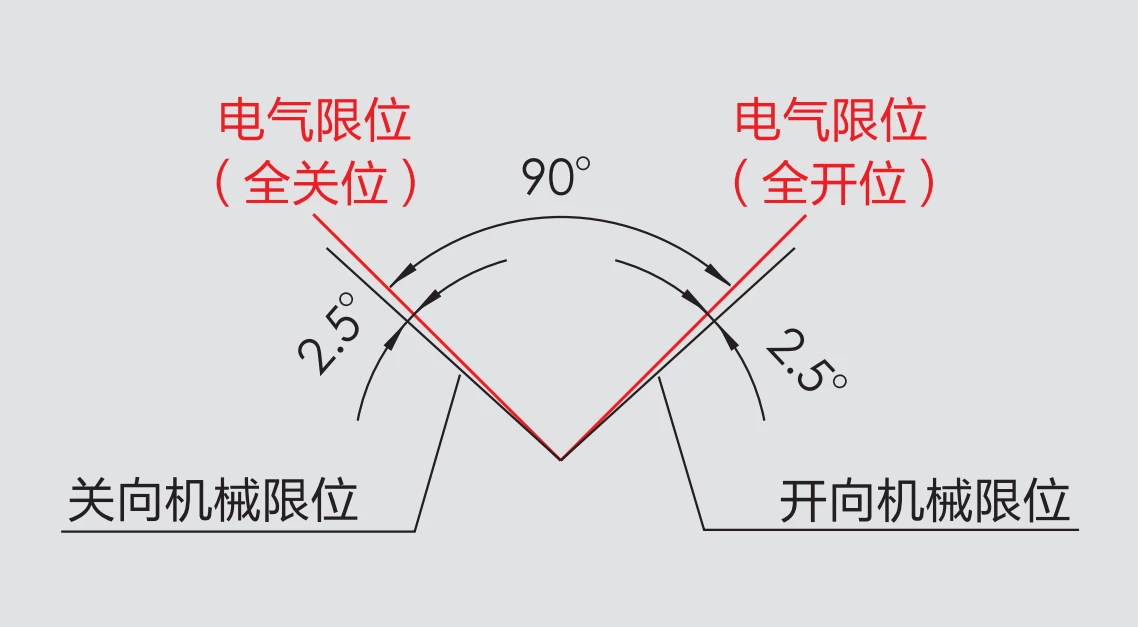

Electrical and mechanical limits

Electrical Travel Limit Function: When the actuator reaches the fully open or fully closed limit position or the set intermediate position, the built-in electrical limit switch will cut off the circuit to protect the actuator.

Output shaft mechanical limit function: In case of electrical travel limit failure, the output shaft of the actuator will be locked by a mechanical limit device, thus protecting the valve from damage.

The diagram shows the positional relationship between the electrical and mechanical limits.

Optional Features

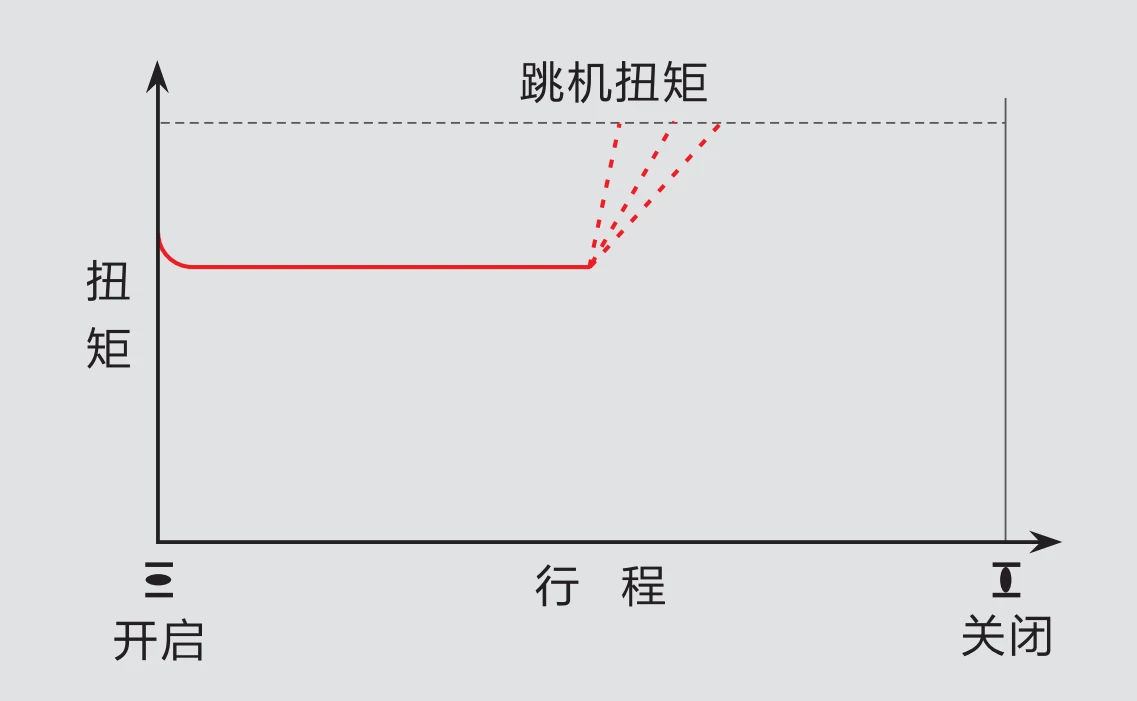

Over-torque protection

When the valve is jammed during operation (intermediate position) due to impurities, foreign matter or other reasons in the pipeline, the output torque of the actuator will increase rapidly, and when it reaches the set value (tripping torque), the torque switch will break the circuit, thus protecting the valve and the actuator from damage.

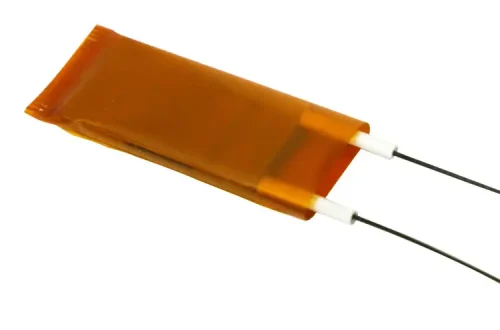

Heating and dehumidifying

The DCL series actuators can be equipped with a PTC electronic heating element in the electrical chamber for use in humid locations with a large temperature difference between day and night to prevent damage to the electrical components due to condensation. The heater is in continuous operation, so it is electrically charged, even when the actuator is not in operation.

Egong.com.cn 42018502006527 No.

Egong.com.cn 42018502006527 No.